Mezzanine vs Multi-Tier Racking: Which Storage Solution Wins?

- Deb Reardon

- Aug 24, 2025

- 2 min read

When warehouses run out of floor space, going upwards becomes the smart choice. Two of the most popular options for maximizing vertical capacity are Mezzanine Floors and Rack-Supported Multi-Tier Systems.

Both can transform underutilized height into valuable storage and picking space—but which one is right for your operation?

Let’s break down the differences, costs, and best-use cases in a way that makes the decision easier.

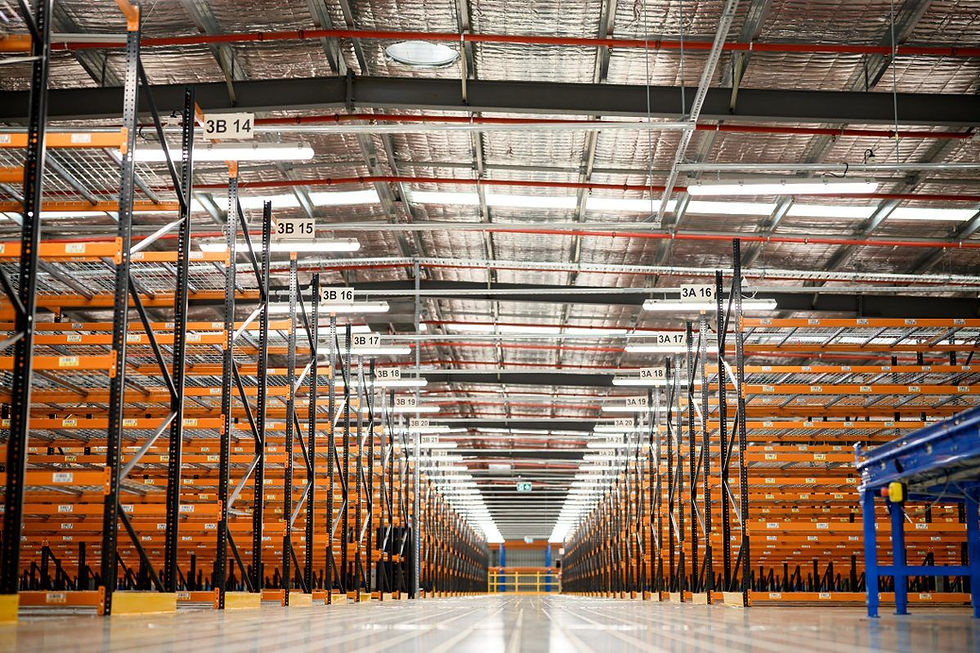

Rack-Supported Multi-Tier Racking

A multi-tier racking system is essentially pallet racking extended into multiple levels, with integrated walkways and stairs built directly into the structure. Think of it as shelving that becomes its own building.

Pros:

High-density storage: 3–5x more capacity in the same footprint.

Cost-efficient: 20–30% cheaper than mezzanine builds.

Faster installation: The racks and walkways are integrated.

Flexible scalability: Easy to expand or reconfigure.

Cons:

Aisles can be narrower than mezzanine setups.

Primarily designed for storage and picking, not mixed-use.

💡 Best for: Warehouses focused on carton picking, e-commerce fulfilment, or operations that want the maximum storage per dollar spent.

Mezzanine Floors + Racking

A mezzanine floor is a freestanding steel platform installed above your warehouse floor. You can put racking below, above, or use it for entirely different purposes like offices or light manufacturing.

Pros:

Versatility: Open-plan design suitable for offices, packing areas, or equipment.

Strength: Can support heavier loads than rack-supported systems.

Custom use: Not limited to storage—great for hybrid warehouse setups.

Cons:

Higher upfront cost due to additional steel structure.

Longer installation and more complex building consents.

Less efficient for high-density storage compared to multi-tier.

💡 Best for: Businesses that need mixed-use space (e.g., offices above, storage below) or want the flexibility to re-purpose upper levels.

Cost Snapshot (NZD)

Project Size | Multi-Tier Racking | Mezzanine + Racking |

Small (500 pallet positions) | $250k – $400k | $350k – $500k |

Medium (1,500 positions) | $600k – $900k | $800k – $1.2M |

Large (3,000+ positions) | $1.2M – $2M+ | $2M – $3M+ |

⚖️ The Decision Matrix

Factor | Multi-Tier Racking | Mezzanine + Racking |

Cost | Lower | Higher |

Storage Efficiency | Excellent | Good |

Flexibility | Storage-focused | Mixed-use (offices, machinery) |

Installation Time | Faster | Slower |

Compliance | Standard | More complex |

🔑 Key Takeaway

Choose Multi-Tier Racking if your top priority is maximizing storage capacity and picking efficiency at the lowest cost per pallet.

Choose a Mezzanine Floor if you need versatility—whether that’s office space above, heavy machinery support, or open-plan flexibility.

In short: if storage is your game, go multi-tier. If flexibility is the aim, go mezzanine.

👉 Considering a new warehouse fit-out in New Zealand? Make sure you factor in seismic compliance, building consent, and fire safety upgrades early in the process. The right choice now will future-proof your warehouse for years to come.

Comments