How to Optimise Warehouse Space with Pallet Racking in New Zealand in 2025

- Deb Reardon

- Aug 21, 2025

- 3 min read

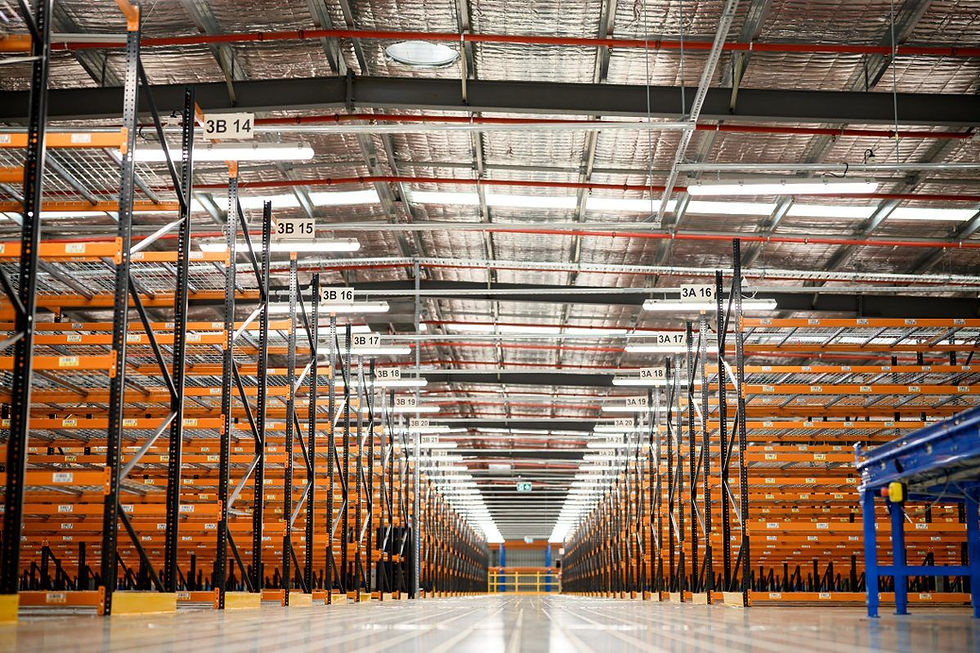

Efficient use of warehouse space is one of the biggest challenges for New Zealand businesses.

Whether you’re running a fast-paced e-commerce hub, a chilled food and beverage warehouse, or a 3PL distribution centre, the right pallet racking system can transform how your space operates.

By combining smart design with modern racking solutions, you can boost capacity, improve workflow, and maintain compliance with New Zealand’s strict safety standards.

Here are some of the key strategies to maximise your warehouse storage and efficiency.

1. Customised Racking Solutions

Every warehouse is different.

Tailoring your pallet racking to suit your specific product types, inventory levels, and picking methods ensures maximum efficiency.

Custom design makes it easier to access products quickly, reduce wasted space, and create safer workflows for your team.

BOP Racking specialists can help you design your efficient space to suit your inventory.

2. Make Use of Vertical Space

Why expand your footprint when you can build upwards?

High-rise pallet racks, mezzanine floors, and even vertical carousel systems allow you to use the full height of your warehouse.

This approach increases storage density without the cost of expanding your building.

3. High-Density Racking Systems

For businesses that need to store large volumes of product, high-density racking systems are essential. Options include:

Double-Deep Racking – storing pallets two-deep to increase capacity.

Drive-In/Drive-Through Racking – ideal for high volumes of the same SKU.

Push-Back Racking – pallets are stored on rails or rollers for efficient retrieval.

Narrow Aisle Racking – maximising space while using specialised forklifts for access.

These systems can significantly increase capacity while reducing the floor space required.

4. Combine Rack Types for Efficiency

No single racking type suits every product. A blended approach – such as selective racks for fast-moving SKUs and drive-in racks for bulk storage – creates a system that balances accessibility and density. This flexibility ensures your storage matches your operations.

5. Use Data to Drive Inventory Placement

Data-driven strategies like ABC analysis and dynamic slotting ensure products are stored in the right place for efficient picking. High-demand products can be placed in easily accessible zones, while slower-moving stock can be stored further away. This reduces travel time and speeds up order fulfilment.

6. Zone Picking Strategies

Designating specific picking zones based on product category or order frequency reduces congestion and improves workflow. Zone picking helps streamline operations, particularly in busy e-commerce and FMCG environments where speed is critical.

7. Safety and Compliance in New Zealand

All pallet racking in New Zealand must comply with safety and seismic standards.

This includes following manufacturer load capacities, ensuring correct installation, and scheduling regular inspections. Compliance not only protects your staff but also safeguards your products and operations.

8. Pallet Stackers for Multi-Tier Efficiency

Adding pallet stackers into your system allows for efficient vertical stacking in multi-tier configurations.

This helps maximise storage density while keeping movement controlled and safe.

Smarter Storage for New Zealand Warehouses

Optimising warehouse space is about more than just fitting in more stock.

It’s about creating a system that improves efficiency, ensures safety, and adapts to your business needs.

At Bay of Plenty Racking – your local Dexion Supply Centre, we design and supply pallet racking solutions tailored to New Zealand’s unique warehousing challenges, from seismic compliance to fast-moving industries.

📞 Contact our team today to find the right racking system for your warehouse.

Comments